Seed Processing

Seed Processing sagemThis section is under construction and new material will be added as soon as it is complete.

Post-harvest processes include drying, pre-cleaning, cleaning, and proper seed storage. The extent of processing required after drying depends on the species, storage conditions, and intended seeding method. Knowledge, skill, and access to specialized equipment are necessary for some of the cleaning steps described, and these factors will determine the quality of the finished product. Most commercial producers of native seed clean seed to a very high quality of purity and germination.

As in other steps in native seed production, care must be taken to avoid selection and loss of genetic diversity in production populations. In seed processing, there is a risk of selecting against genes that influence seed traits. For example, if only average-sized seeds are kept and used for expanding or re-growing fields, genes for seeds that are smaller or larger than average can decline in the population within a few generations.

- Drying

Drying is a necessary step for proper seed cleaning and storage for nearly all prairie species. Seed should be dried immediately after harvesting to prevent fungal growth and decomposition. Plastic bags or airtight containers can be used for storage ONLY after the seed is properly dried and cleaned. Larger quantities of material require specially constructed bins with screened bottoms and a source of airflow up through the material. Smaller quantities can be collected in large 100% cotton muslin bags made to fit inside a 30-gal plastic trash bin. Large cotton laundry bags with drawstrings work well. Fill bags loosely with seedheads, tie closed, label, and place in drying bins. If the material associated with the seed is very green, as is the case with spiderwort (Tradescantia spp.), or is damp from a recent rain shower, spread the material out on tarps and position several box fans overhead, turning the seed frequently with pitchforks, rakes, or shovels. Drying may take several days to a few weeks, depending on quantity of material and drying conditions (ambient humidity).

Image 1: Bin suitable for drying seed in cloth bags.

Image 2: Cut stalks of Tradescantia bracteata laid to dry on a tarp. - Pre-cleaning

Harvested material requires some degree of pre-cleaning to reduce bulk. The extent of pre-cleaning required depends on the method of seed harvest, intended storage period, and method of planting. Threshing, debearding/deawning, and brushing are considered pre-cleaning steps, because they are designed to prepare the seed for later cleaning processes by removing unnecessary appendages and improving seed flow.

Threshing

Threshing removes the seed from seedheads, one of the primary functions of a combine harvester. Hand-collected material can be threshed with a variety of machines, including hammer mills, huller/scarifiers, and brush machines. Some growers have adapted older combines (with cutter bars and reel removed for safety) for use as a stationary thresher of hand-collected material. A debearder (see below) is effective for removing the awns of grass seeds and threshing the dried seedheads of compassplant and dried milkweed pods.

Image 3: Adding dried milkweed pods to the hopper of the Westrup debearder.

Image 4: Seed falls into a tub positioned below the debearder, mixed with chopped pods and fluff. Non-mechanized threshing can be accomplished by stomping on seedheads. Using large plastic tubs, place about a 2-in. layer of bulk material in the bottom and stomp on it with waffle-sole boots. Toe kicks to the corners of the tub help break up any stubborn seedheads. Stomped material is then screened through a coarse ½-in. or ¼-in. screen into a second tub. Continue in batches, returning any intact seedheads remaining to the stomping tub. This method is very effective on species of Baptisia, Silphium, Helianthus, Veronicastrum, and Rudbeckia. Echinacea tends to be stubborn and requires machine threshing, unless it is collected late in the season after the seedheads naturally begin to shed their seed.

Deawning/Debearding

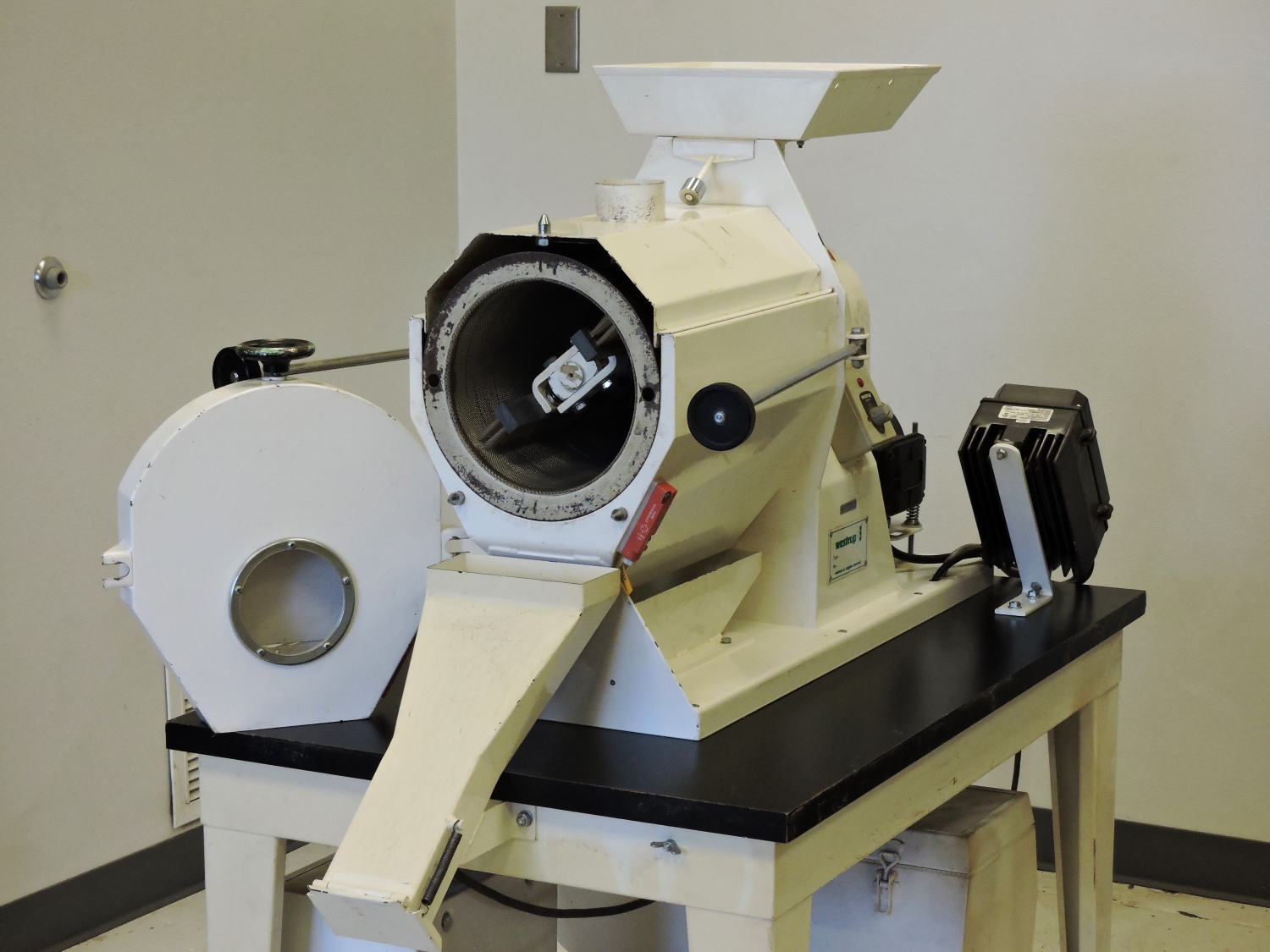

Many species have seed appendages such as the awns or “beards” on grasses and pappus “parachutes” on seeds of asters, goldenrods, and other composites. Removing or minimizing these appendages reduces bulk and improves seed flow for further cleaning. This step requires specialized and costly equipment. Debearding machines consist of a rotating shaft with projecting metal bars housed in a chamber. As the chamber fills with seed, the bars work the seed against itself, breaking or rubbing off the awns. It is important to fill the chamber with the proper amount of seed: too little and it’s ineffective, too much and the seed can heat up and be damaged. A continuous flow debearder works well for larger quantities of seed, but batch debearders are available for smaller quantities. A small gallon-size huller/scarifier is useful for deawning small individual accessions of seed. This type of machine is very aggressive, and only a few seconds of treatment are typically needed.

Image 5: A debearder being used to improve the flowability of combine harvested big bluestem (Andropogon gerardii) before cleaning the seed. A brush machine is useful for removing the pappus from asters, goldenrods, and blazing stars, but this versatile machine has many uses. Its basic action is to use rotating brushes to rub seeds or seedheads over a cylindrical drum screen, or mantle. Mantles come in various screen sizes, and a variety of brush textures is available. The machine can also be used as a deawner or scarifier. It is effective in removing the “cotton” from thimbleweed (Anemone virginiana and A. cylindrica), threshing seed from hand-collected mint seedheads, removing pods from purple prairie clover and leadplant, and deawning smaller quantities of grasses. Heavy canvas beater bars can be installed in place of brushes for a hammer-mill-like effect for removing seed from tough legume pods (e.g., Amorpha spp., Dalea spp., and Astragalus spp.) and dried rosehips (Rosa spp.). Beater bars are constructed from rubber/canvas multi-ply conveyer belting which can be purchased from industrial supply companies and cut to fit. When setting up the machine, position the beaters so that the canvas is barely touching the edge of the screen.

Image 6: A laboratory scale debearder with the front cover removed to show the screen mantle and rotating brushes.

Image 7: A student worker feeding dried rosehips into the brush machine which has been set up with canvas beater bars.

Image 8: The brush machine with beaters installed crushes the rosehips and releases the seeds. - Cleaning

- Storage